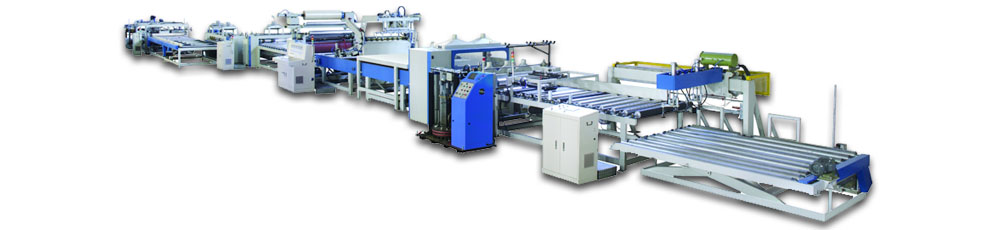

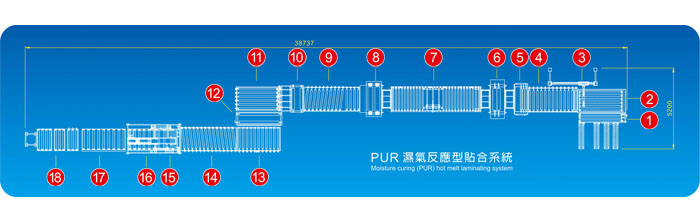

MOISTURE CURING(PUR)

Product Introduction

FEATURES

- Breakthrough technology incorporating specially PUR moisture curing hot melt glue apply on board.

- High productivity up to 40 metres / min.

- This line is capable of simultaneous double sided lamination.

- The thermo-oil heated press rolls are specially constructed to realise a high and even temperature of 200°C in a short time. This high temperature is critical for an excellent glue bond.

ADVANTAGES OF OF SYSTEM

- Products can be cut immediately after lamination.

- Harder laminated surface.

- Better pore filling when using inferior quality boards.

- Excellent adhesion and high stability under damp and hot conditions.

- RAW MATERIALS NEEDED :

A. Base Material:Wood board,Metal board,Plastic PC board.

B. Top Material:Decoratire paper,Hight-gloss PVC,Acrylic sheet,Metal sheet.

C. Glue:PUR moisture curing hot melt glue,PVAc glue,EVA glue,Mixing UF glue - BOARD SIZE :

All flat boards of the following sizes may be used:

A. Thickness: 2-30 mm

B. Width: 900-1250 mm

C. Length: 1800-2470 mm - CAPACITY:

Line speed capability : 5-40 meteres per minute - NUMBER OF OPERATORS:

2 operators for the whole line - ELECTRIC POWER:

Motors: 40 HP ( 30KW )