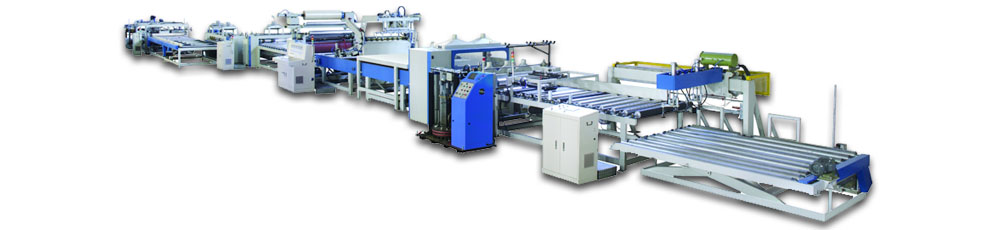

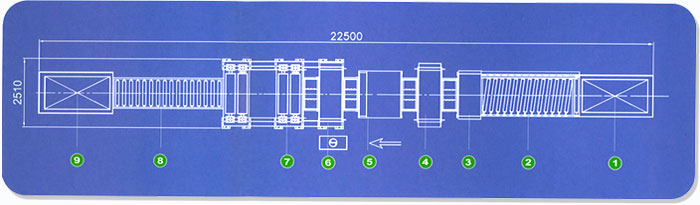

WTLU-D35

Product Introduction

ADVANTAGES OF OF SYSTEM

- Products can be cut immediately after lamination.

- Harder laminated surface.

- Better pore filling when using inferior quality boards.

- Excellent adhesion and high stability under damp and hot conditions.

FEATURES

- Breakthrough technology incorporating specially Modified urea formaldehyde glue with hardener and resin applied by separate spreaders.

- High productivity up to 40 metres / min.

- This line is capable of simultaneous double sided lamination.

- The electrically heated press rolls are specially constructed to realise a high and even temperature of 200°C in a short time. This high temperature is critical for an excellent glue bond.

- RAW MATERIALS NEEDED :

Plywood, particleboard, cardboard, MDF board, etc.

Decorative printed paper or PVC foils.

Urea formaldehyde glue for impregnated finished foils.

PVAc emulsion glue for paper.

EVA emulsion glue for PVC foils. - BOARD SIZE :

All flat boards of the following sizes may be used:

Thickness: 2-30 mm

Width: 900-1250 mm

Length: 1800-2470 mm - CAPACITY: Line speed capability :

5-40 meteres per minute - NUMBER OF OPERATORS:

2 operators for the whole line - ELECTRIC POWER:

Motors: 116 HP ( 87KW )

Heaters:130 KW